The Promise of 3D Printing: Transforming Manufacturing and Design

Imagine entering an era where manufacturing and design are no longer confined to conventional methods and mass production. You now have the power to unlock a new world of possibilities with 3D printing, filled with excitement, ingenuity, and a touch of pure magic.

Take a moment to grasp just how special 3D printing truly is. It’s like having a secret superpower, allowing you to transform digital blueprints into tangible objects, layer by layer. Picture yourself bringing intricate prototypes, stunning sculptures, and personalized creations to life, tailor-made to suit your individuality.

At its core, 3D printing builds three-dimensional objects layer by layer based on a digital model. Unlike traditional methods that involve cutting or shaping materials to create an object, this adds material incrementally to construct the final product. This layer-by-layer approach gives rise to its name, as the thing is built up in successive layers. You play a crucial role in 3D printing through the digital design file, which serves as the blueprint for printing the object. You can create this digital file using computer-aided design (CAD) software, providing precise instructions on how the printer should build each layer of the thing. Once you’ve prepared the design file, you can send it to the 3D printer, which interprets the instructions and begins printing.

The actual process of this printing varies depending on the technology you use. There are several methods available. Each technique utilizes different materials, such as plastics, metals, ceramics, or even biological materials, and employs various mechanisms to deposit or solidify the material in a controlled manner.

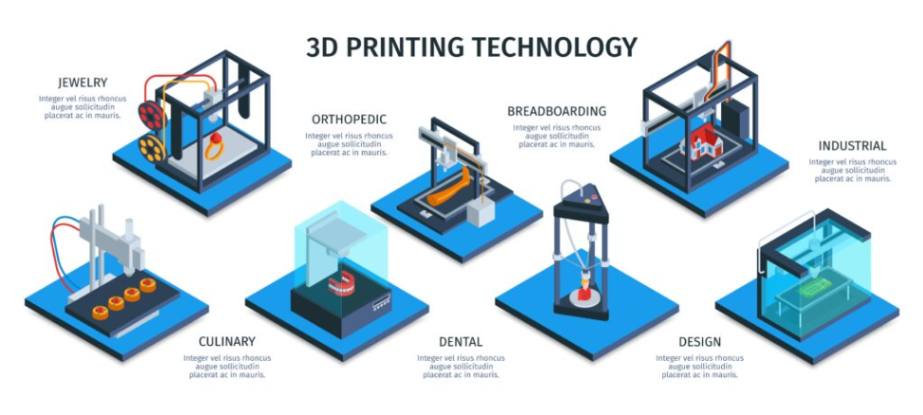

The applications of 3D printing span a wide range of industries and disciplines. It has revolutionized the prototyping process in manufacturing, allowing for rapid iterations and design improvements. Instead of waiting weeks or months for a prototype to be produced using traditional methods, 3D printing enables you to create physical prototypes in hours or days, accelerating the product development cycle.

Beyond prototyping, 3D printing is increasingly being utilized for end-use part production. Complex geometries, intricate designs, and customized components that were once challenging to manufacture are now within your reach, thanks to the design freedom offered by this technology. Industries such as aerospace, automotive, healthcare, and consumer goods are embracing 3D printing to create lightweight structures, bespoke medical devices, personalized consumer products, and more.

Advantages of 3D Printing in Manufacturing

Let’s explore the key benefits that make 3D printing a revolutionary force in manufacturing.

Design Freedom and Complexity: One of the most significant advantages of 3D printing lies in your unparalleled design freedom. Unlike traditional manufacturing techniques that limit design due to production constraints, 3D printing allows you to quickly create complex and intricate geometries. The layer-by-layer additive process enables the production of organic shapes, intricate details, and internal cavities that were once challenging or impossible to achieve. This newfound design freedom unlocks limitless possibilities for innovation and enables the creation of highly customized and unique products.

Rapid Prototyping and Iteration: Time is of the essence in the manufacturing world, and 3D printing offers you a remarkable advantage in rapid prototyping and iteration. Creating prototypes with traditional manufacturing methods often involves time-consuming and costly processes, such as molding and tooling. In contrast, 3D printing allows for the swift transformation of your digital designs into physical prototypes, reducing the time and cost associated with prototyping. This speed and agility facilitate iterative design improvements.

Cost-Effectiveness and On-Demand Production: With this printing, you can take advantage of cost-saving opportunities and shift towards on-demand production. You no longer need to make significant upfront investments in tooling, machinery, and inventory as required in traditional manufacturing. Instead, 3D printing allows you to produce parts and products as needed, eliminating the need for large production runs and excessive inventory. This on-demand approach not only reduces storage costs but also minimizes waste and enables cost-effective small-batch or customized production. It allows you to consolidate multiple parts into a single printed component, simplifying assembly and lowering production costs.

Complexity at No Additional Cost: When it comes to design complexity, traditional manufacturing often incurs additional expenses due to specialized tooling and processes. However, 3D printing overcomes this hurdle by offering complexity at no additional price. Whether it’s intricate shapes, internal channels, complicated lattice structures, or highly detailed surfaces, 3D printing can efficiently produce these complex features without incurring extra costs. This unique advantage empowers you as a product designer to create highly optimized and innovative designs without compromising on cost efficiency.

Customization and Personalization: In today’s market, consumer demands are increasingly leaning toward personalized and customized products. This is where 3D printing excels by delivering tailored solutions through mass customization. Its digital nature allows you to easily customize designs to meet individual customer preferences and requirements. Whether it’s personalized medical implants or customized consumer goods, 3D printing gives you the power to offer unique and bespoke products, ultimately enhancing customer satisfaction and fostering customer loyalty.

Reduced Material Waste and Environmental Impact: Traditional manufacturing methods often result in significant material waste through subtractive processes, where excess material is removed to shape the final product. However, 3D printing operates through an additive process, using only the necessary amount of material to create the object, thus minimizing waste. 3D printing enables the utilization of recycled or biodegradable materials, contributing to a more sustainable manufacturing ecosystem. By reducing material waste and energy consumption, 3D printing brings environmental benefits and aligns with the growing focus on sustainability.

Applications of 3D Printing in Different Industries

Let’s explore how 3D printing is making a profound impact in various sectors. We’ll delve into the applications of 3D printing in different industries, where you can witness the fusion of Indian culture and innovation with this transformative technology.

Healthcare: You can see the remarkable advancements that 3D printing has brought to India’s healthcare industry. It enables the creation of customized prosthetics, implants, and patient-specific medical devices, providing precise and tailor-made solutions. This technology empowers healthcare professionals like you to deliver personalized care in a diverse country like India, where anatomical variations are abundant. 3D printing holds immense potential for bioprinting, which may one day lead to the creation of living tissues and organs, bringing us closer to a future where organ transplantation is more accessible.

Aerospace and Defense: In India’s aerospace and defense sectors, 3D printing has quickly gained momentum. By utilizing this technology, you can create intricate components with reduced weight, ensuring fuel efficiency and enhanced performance. For a country with notable space exploration endeavors, 3D printing streamlines manufacturing processes, accelerates prototyping and enables the production of critical parts on demand. This cost-effective approach strengthens our indigenous capabilities in the aerospace and defense domains.

Automotive: The Indian automotive industry, known for its innovation and expertise, is embracing 3D printing to revolutionize manufacturing. As an automotive professional, you can benefit from rapid prototyping, allowing you to refine designs swiftly. 3D printing facilitates the creation of custom tooling, jigs, and fixtures, improving production efficiency and reducing costs. This technology empowers automotive enthusiasts like you to manufacture low-volume or specialized components, enabling the manifestation of unique and customized vehicles.

Fashion and Design: India’s rich heritage of textiles and craftsmanship merges beautifully with 3D printing in the realm of fashion and design. Designers now have the freedom to experiment with innovative materials and intricate patterns, pushing the boundaries of creativity. By incorporating 3D printing, you can create bespoke jewelry, accessories, and even intricately designed garments. This blending of traditional craftsmanship with cutting-edge technology gives Indian craftspeople a platform to present their abilities on a large scale.

Architecture and Construction: India’s architectural marvels and diverse construction projects find a natural ally in 3D printing. This technology empowers architects and engineers like you to transform digital designs into physical structures with intricate detailing. Whether it’s building models or complex structural components, 3D printing enables faster prototyping, reduces material waste, and unlocks possibilities for sustainable construction practices. With its potential to address housing challenges and provide affordable housing solutions, 3D printing holds great promise for the Indian construction industry.

Education and Research: In India’s vibrant educational landscape, 3D printing has become an invaluable tool for experiential learning and research. You may put your thoughts into practice as a student, bridging the gap between theory and practice. Educational institutions can utilize 3D printing to create teaching aids, anatomical models for medical education, and prototypes for scientific experiments. By integrating this technology into the curriculum, India’s future generations can nurture their innovation and problem-solving skills.

As we witness the synergy between 3D printing and Indian industries, a world of opportunities unfolds. The versatility of this technology, combined with India’s rich cultural heritage and entrepreneurial spirit, paves the way for groundbreaking solutions and transformative growth. Embracing 3D printing opens doors to innovation, empowers local manufacturing, and strengthens our position on the global stage. The future holds immense promise as we embark on this journey of technological advancement and creative exploration.

Challenges and Limitations of 3D Printing: A Journey of Overcoming Obstacles

a. Material Constraints: 3D printing materials have come a long way, but there are still limitations compared to traditional manufacturing. Certain specialized materials, especially those with high heat resistance or complex properties, pose challenges for printing. Overcoming these limitations and expanding the range of compatible materials will be crucial for unlocking new applications.

b. Speeding Up Production: 3D printing can be slower, particularly for large-scale or intricate objects. In a country like India, with a vast manufacturing landscape, speeding up production while maintaining quality is a priority. Innovations in printing technologies and optimization of print parameters are essential to faster and more efficient manufacturing.

c. Ensuring Consistency and Quality: Consistency and quality control are vital for industrial applications. Achieving consistent prints with reliable mechanical properties can be challenging, given the dependence on factors like temperature, layer adhesion, and surface finish. Striving for improved consistency and developing robust quality assurance measures will build trust and confidence in 3D-printed products.

d. Post-Processing Refinements: Many 3D-printed objects require post-processing to achieve the desired aesthetic and functional attributes. Polishing, painting, or surface treatment may be necessary to enhance the final product. Streamlining post-processing techniques and exploring new finishing methods will optimize efficiency and reduce costs.

e. Intellectual Property Protection: With the democratization of 3D printing, protecting intellectual property becomes paramount. Safeguarding original designs from unauthorized reproduction and ensuring compliance with copyright laws are ongoing challenges. Developing effective strategies, such as digital watermarking or encryption, will help protect the rights of designers and innovators.

Future Potential and Emerging Trends

Embracing Innovation on Indian Soil Despite the challenges, the future of 3D printing in India holds immense promise, with several emerging trends shaping its trajectory

a. Advanced Materials: Indian researchers and material scientists are exploring new frontiers in 3D printing materials. The objective is to broaden the range of potential uses for diverse applications, ranging from biodegradable polymers to metal alloys, in industries including healthcare, aerospace, and automotive. This pursuit will lead to groundbreaking advancements, strengthening India’s position as a global hub for material innovation.

b. Localization and Customization: 3D printing offers localized manufacturing and customization potential, aligning with India’s diverse consumer needs. By decentralizing production and enabling localized fabrication hubs, we can reduce transportation costs, minimize inventory, and cater to unique regional demands. This trend empowers local businesses and artisans, fostering economic growth and nurturing indigenous talent.

c. Sustainable Solutions: As India embraces sustainable development, 3D printing can contribute significantly to eco-friendly manufacturing practices. By minimizing material waste through additive manufacturing and utilizing recycled or biodegradable materials, we can reduce the environmental impact of production processes. This aligns with India’s commitment to sustainable growth and preserving our natural resources for future generations.

d. Collaborative Ecosystems: The Indian 3D printing community is witnessing a rise in collaboration between researchers, industry experts, and entrepreneurs. Universities, startups, and established companies are joining forces to drive innovation, share knowledge, and overcome challenges collectively. This collaborative ecosystem fosters a spirit of entrepreneurship and nurtures the growth of India’s vibrant 3D printing industry.

Embracing the Journey Toward a 3D-Printed Future as an Indian writer, I am excited to witness the transformative potential of 3D printing in our country. By addressing challenges and limitations, we can unlock the true power of this technology and create a future where localized manufacturing, customization, and sustainable practices thrive. India is positioned to lead the global 3D printing revolution with invention, teamwork, and a persistent dedication to overcoming challenges. Let us embrace this journey with enthusiasm, curiosity, and a spirit of ingenuity as we shape a future where the extraordinary becomes a reality.